Twin 5300(V) 316L

Twin 21300(H) 316L

Twin 16500(H) 316L

Seen underway on our factory floor, three differently sized and configured Omicron solutions.

We start the gallery of solutions for domestic water filtration in whole buildings with our largest simplex -- with 21,300 cm2 of screen area.

When the goal is reliable fine filtration, size matters.

The more screen surface area, the greater the ability of the filter to capture variable and high dirt loads while maintaining uncompromised operation.

Omicron 21300-10(H) 316L PN16 installed. Note our model numbers provide important info:

21,300 cm2 of screen area, 10 micron, H for horizontal orientation of the housing, 316L stainless, PN16 medium high pressure -- up to 230 psi.

(Standard is PN10 up to 150 psi, PN25 is our max high pressure unit for up to 360 psi.)

1.

Omicron 21300-10(H) 316L PN16 [pressure rated up to 230 psi] installed downstream of house pumps. High pressure into the filter supports reliable 10 micron filtration, and no flush pump is required for backwash cycles. Project values: max pressure 165 psi, max flow rate 215 gpm.

The same Omicron 21300-10(H) is available in coated carbon steel (CCS) as a cost-saving choice that is otherwise identical in product water quality delivered at the required flow rate. Model shown is PN25, for installation in a high-rise building downstream of the house pumps.

2.

To deliver the same water quality at a much higher flow rate, we supply the 21300 unit in a duplex version, with 42,600 cm2 of total screen area.

This is used ever more often to meet the demand of today's multi-residential buildings with exceptionally high flow rates, typically in the 500 - 900 gpm range.

Shown: Twin version skidded as a stacked configuration for the most efficient footprint.

3.

If the footprint calls for a horizontal orientation but for reasons of ease of maintenance and/or you have more available Width than Height, here is a side-by-side orientation of our Twin 21300 providing the same 42,600 cm2 of screen area.

4.

Twin 21300-10(H) 316L near completion on the factory floor. This model includes a flush line suction pump (mounted on skid base) to ensure adequate backwash pressure during flush cycles, often needed when the system is installed for domestic water at net street pressure.

5.

Side-by-side orientation of our Twin 21300-10(H) 316L retrofit into a 60-story Brooklyn residential building that suffered ever since its opening from severe Turbidity – until they invested in our 10 micron solution with enough capacity to handle the most extreme dirt loads that regularly enter the domestic water supply.

A richly informative HMI panel is typically side-mounted on the skid so as not to increase the clearance length requirement.

Twin 21300-10(H) 316L installed, front view showing flush line pump in foreground.

If the available footprint is tight but there is plenty of height, here is a vertical orientation of our Twin 21300 providing the same 42,600 cm2 of screen area, with required screen pullout clearance above the filters.

6.

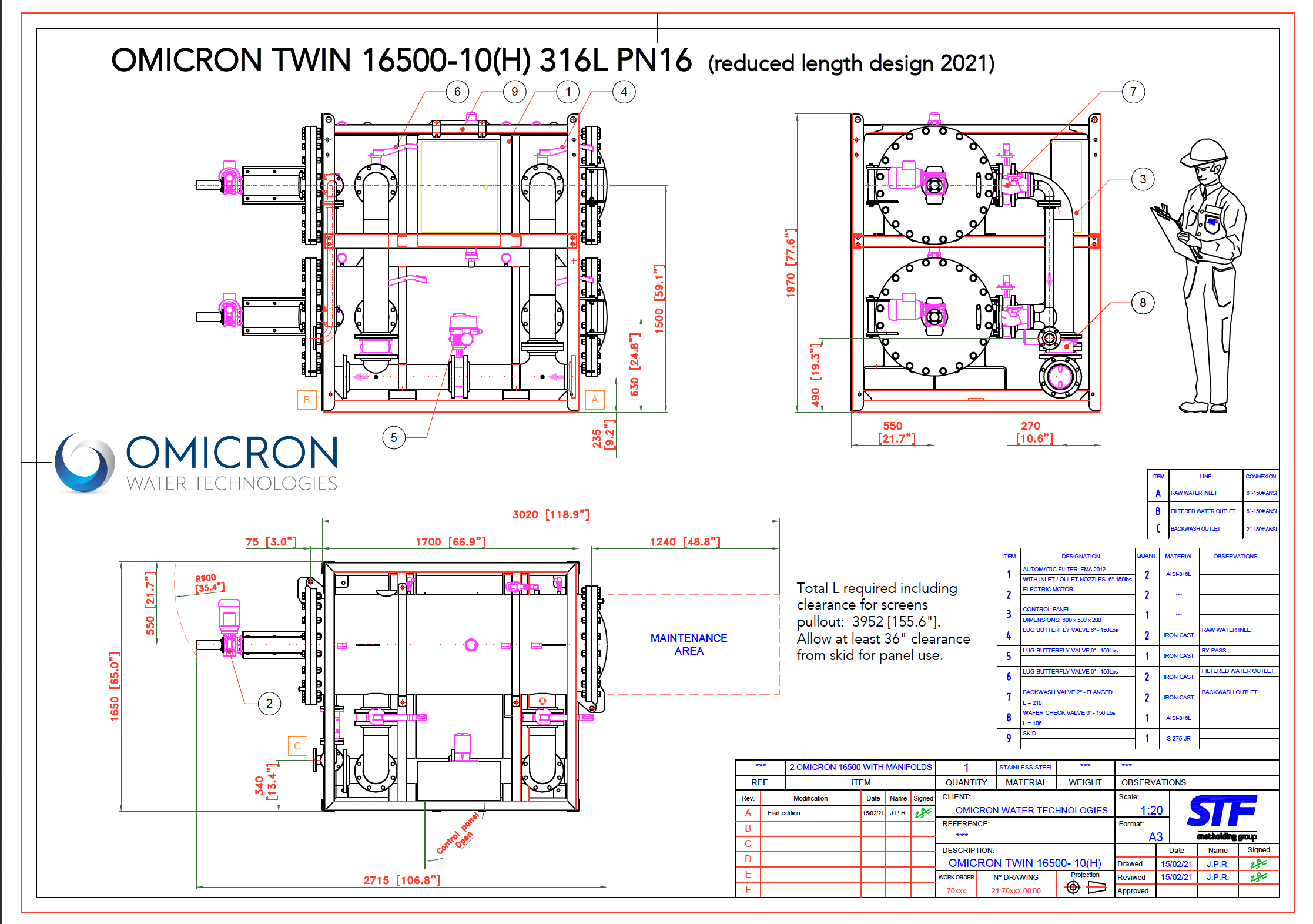

Our single most specified solution is a Twin 16500-10(H) 316L -- in standard pressure (PN10), up to 230 psi (PN16) or up to 360 psi (PN25).

The 16500 housing is the same 26" diameter as the 21300, but shorter.

Overall the skid (including allowing for screen pullout clearance) saves about 22" in length compared to a 21300.

For many projects a Twin 16500 with 33,000 total screen area is adequate to accommodate the max flow rate of a typical triplex booster pump skid to roof tank fill or on constant pressure, even at 10 micron.

7.

Shown: Omicron Twin 16500-10(H) 316L PN25

The same skidded solution also available with housings in NSF Standard 61 coated carbon steel (CCS). Performance and product water quality are identical to the 316L versions, ordered as the single least compromising VE imperative.

8.

The 16500 model is of course also supplied as a simplex for smaller flow rates, equally available in CCS or 316L.

9.

Drawing of our most compact design of a skid with 33,000 cm2 of screen area. Note how much of the overall space occupied by the system is dedicated to actual filtration area rather than the manifold. More filtration in less space is always the goal.

10.

Drawing of a skidded duplex by another manufacturer that occupies the same footprint as an Omicron Twin 16500 – and yet only provides 9000 cm2 of screen area compared to ours with 33,000 cm2. That’s not even 28% of our solution’s capacity – in the same footprint. The inefficient use of available space from a “competitor” is clear when comparing the two drawings.

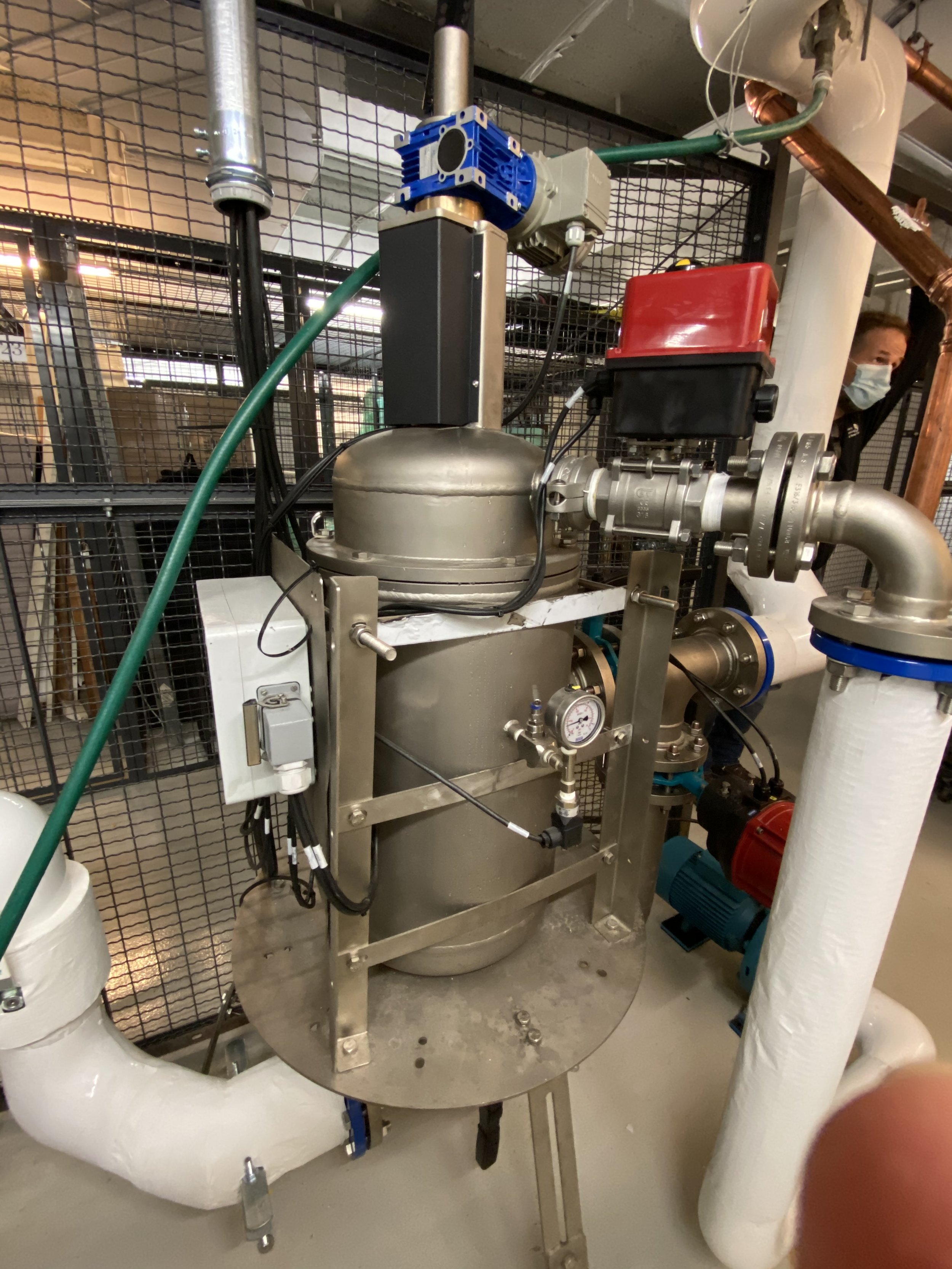

Omicron 10600-10(H) 316L installed on domestic water, new construction. Available footprint was highly constrained. The unit was ordered without a skid to accommodate the tight fit. Flush pump seen in foreground, control panel is wall-mounted behind filter.

For smaller flow rates, typically 100 gpm, a smaller model works. Note this simplex 10600 still has more screen area than a standard duplex SAF4500 (9000 cm2 total screen area) typically offered by competition. At a lower cost, smaller footprint and simpler build and install.

11.

The precisely defined Omicron 5300-25(V) 316L build approved by the New York City School Construction Authority (SCA) for new NYC public schools, shown here nearing completion at the factory.

This ongoing SCA requirement started in 2020, with Omicron rapidly becoming the most frequently ordered solution by the many plumbing contractors awarded these projects.

Provides 5300 cm2 of screen area in order to assure meeting the SCA’s requirement for 25 micron filtration at up to 200 gpm.

Supplied with a detachable platform for stability, which can be deleted in the field if the available footprint does not allow.

12.

This same model 5300(V) is often used in other circumstances where available space is especially tight, often in retrofit applications.

13.

Retrofit installation of Omicron 5300(V) 316L showing the piping in and out.

Another look at this retrofit installation with the actuator, pressure gauge, discharge to drain and flush pump in view.

Model 5300(V) is often manifolded as a duplex or triplex, in order to accommodate higher flow rates and/or a finer filtration degree with great adaptability to available space.

14.

A compact duplex configuration often used where the available footprint is tight, new construction or retrofit: Twin 5300(V) with 10,600 cm2 of screen area, all 316L stainless, fabrication underway at our factory.

15.

Installation view: A compact solution where space is limited. Twin 5300(V) 316L, with the panel wall-mounted to optimize adaptability to the available footprint.

A close up view of the compact Twin 5300(V).

A retrofit solution where the available footprint was constrained, but the building required 10 micron and a variable flow rate through a constant pressure system. Triple 5300-10(V) 316L. The three filters were moved into place one at a time and manifolded by the contractor once inside the room.

16.

The control panel is mounted on the wall to assure flexibility of installation.

View of the retrofitted Triple 5300(V) showing manifold.